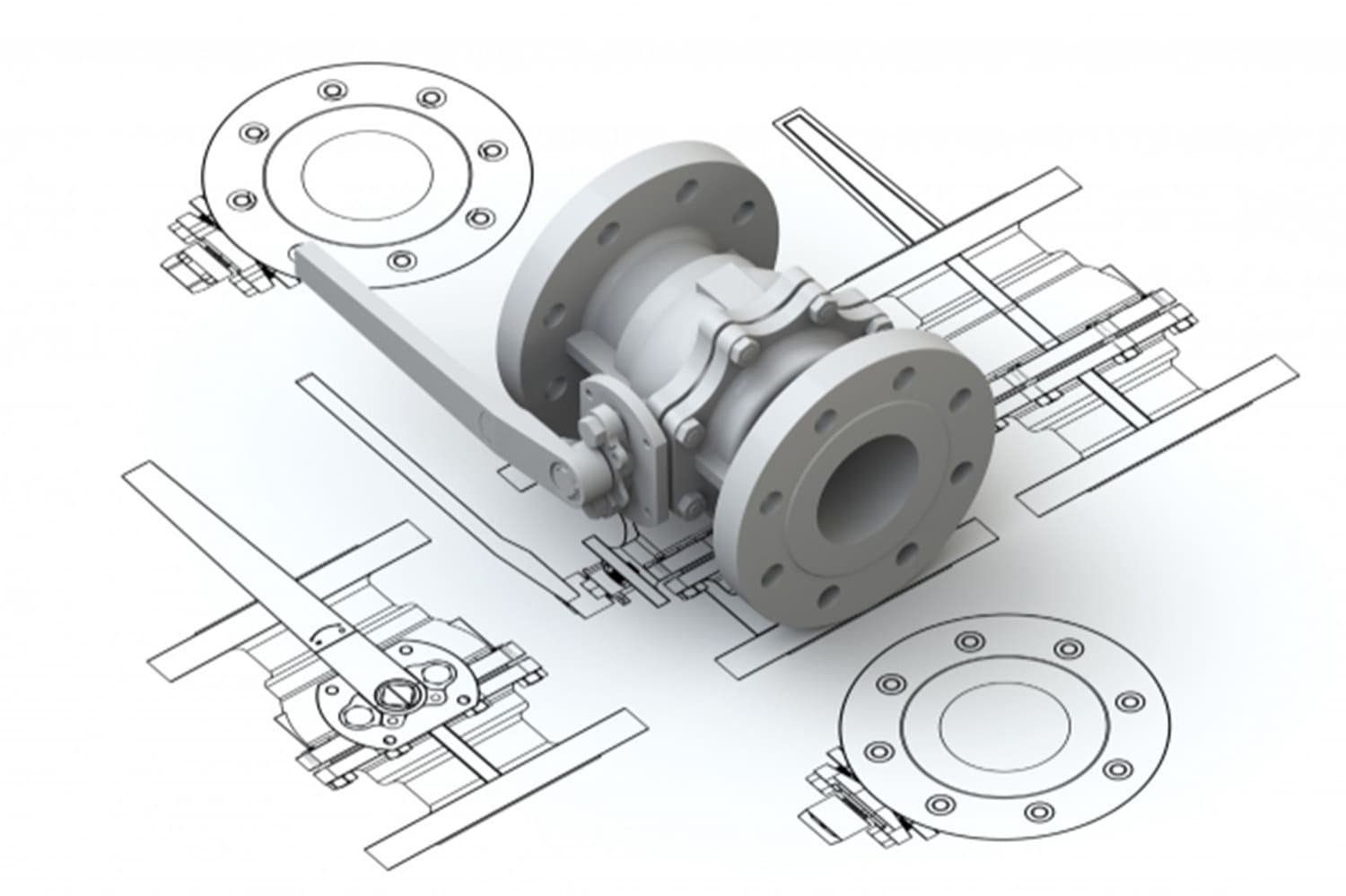

Our journey begins with a team of skilled engineers who meticulously design products that not only meet but exceed industry standards. We focus on functionality, material selection, and production feasibility to create blueprints that set the foundation for excellence.

Precision is the key to success. Our in-house die manufacturing ensures that the tools and molds used in the shaping process are crafted with the utmost accuracy and precision, guaranteeing a flawless production cycle.

Quality is non-negotiable. Before any production begins, our raw materials undergo rigorous testing to ensure they meet our stringent standards. This commitment to quality guarantees the integrity and performance of the final product.

Shaping possibilities, one cut at a time. Our cutting process involves the use of state-of-the-art tools and techniques to create the initial form of the product with precision and efficiency.

Harnessing the power of controlled temperatures, our heating process prepares materials for further manipulation, enhancing their properties and setting the stage for the forging process.

Strength through shaping. Our forging process employs skilled craftsmanship and advanced techniques to align the grain structure of metals, resulting in products with unparalleled strength and durability.

Precision meets temperature control. Our in-house heat treatment ensures that each product undergoes a tailored heating and cooling process, optimizing mechanical properties for superior performance.

Surface perfection is our standard. Through shot blasting and fettling, we refine surfaces with precision, ensuring a flawless finish that meets the highest aesthetic and functional standards.

Zero compromises on quality. Our rigorous inspection process includes crack detection, hardness testing, and quality assessments to verify that each product meets and exceeds specified standards.

Precision at the core. Our CNC machining process utilizes cutting-edge technology to achieve unparalleled accuracy, allowing us to meet tight tolerances and deliver products of the highest caliber.

Seamless delivery, every time. Our commitment to excellence extends beyond production. Our logistics team ensures efficient planning and coordination, guaranteeing timely delivery and seamless integration into the supply chain.